The Definitive Guide for Aws Cwi

The Definitive Guide for Aws Cwi

Blog Article

The Greatest Guide To Aws Cwi

Table of ContentsNot known Facts About Aws CwiAws Cwi Fundamentals ExplainedSome Known Factual Statements About Aws Cwi The Facts About Aws Cwi UncoveredAws Cwi - The Facts

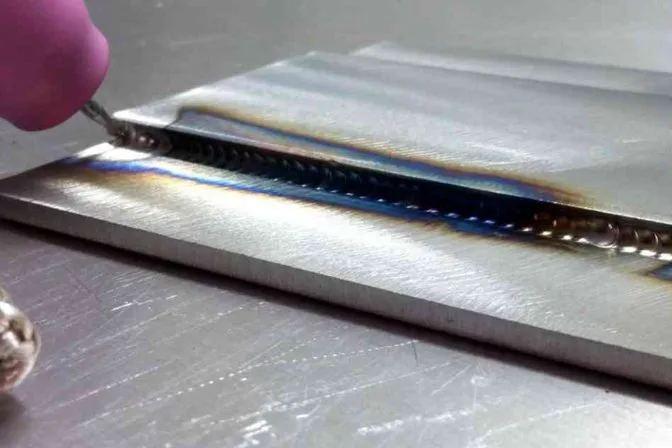

Third-party quality assurance assessment of steel construction fixate welding evaluation, along with inspection of bolting and painting of structural steel. KTA's steel examiners provide Quality assurance (QC) inspectors to supplement maker's/ contractor's internal QC staff and on jobs that mandate preserving the solutions of a certified inspector (e.g., CWI) employed by an independent evaluation firm.Assessors carry out visual examinations of material for uniformity with the authorized specifications, strategies and codes, along with confirmation of Qualified Material Examination Reports (CMTR) for products used. Products and components are observed at vital factors along the manufacturing procedure in both steel mills and steel construction stores. KTA's qualified welding examiners additionally witness welder and welding treatment certification tests as relevant to the extent of the task.

Steel manufacture assessment solutions likewise consistently consist of executing non-destructive screening (NDT), also known as non-destructive examination (NDE), including Magnetic Bit Examining (MT), Ultrasonic Screening (UT) and Fluid Penetrant Checking (PT). KTA's examination solutions consist of finish inspections covering surface area preparation, painting, galvanizing, and metalizing.

KTA's ideology is to react promptly to customers' needs, match the ideal assessor to the work, and give the requisite paperwork. KTA has the support employees to supply technological consulting to the area personnel and to the client. KTA has professionals offered to consult on welding, NDT and finishings.

FST Technical Solutions is your international companion in the Semiconductor and Drug Industries! Our placements consist of advantages such as medical, dental, vision, life, 401(k) with business match, PTO, paid holidays. Come join an outstanding team in an interesting, rapid paced, and ever-growing industry! We are seeking a CWI's and/or NDT Level II licensed Welding Inspectors from around the Lithia Springs, GA location! Town prospects are motivated to apply however this position is open to tourists with mobilization and monthly per diem for those living outside the town.

Aws Cwi Things To Know Before You Get This

Semiconductor, Customer Products, Biography & Biopharmaceutical, and so on. Ideal prospect will have high pureness piping examination experience. Existing AWS certs are preferred. CWI's and NDT Degree II's extremely motivated to use.

Pro QC's third-party welding assessment services include: Record Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Screening (NDT) Others Our welding assessment reports are delivered within 24 hours and record all examination factors relevant to top quality, including all identified weld blemishes and electronic photos (AWS CWI) (https://www.folkd.com/profile/222300-awscw1w3lding/). Pro QC's team of examiners provides third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and a lot more countries

Examination of the welding work is essential for correct quality When your firm is handling major jobs with requirements for 3rd party independent welding assessment, we give exceptional welding witness assessment services to confirm that welding has actually been executed according to a lot of applied welding standards and specifications. AQSS performs welding evaluation services for customers from a range of sectors.

Excitement About Aws Cwi

Not adhering to appropriately certified welding procedures typically results in a weld of substandard high quality, which can boost the manufacture's probability of failure under intended solution problems. By checking for issues, our inspectors can help customers ensure that their welds fulfill pertinent criteria of quality control (Welding Inspection Agency). Weld examinations are conducted for numerous reasons, the most usual of which is to figure out whether the weld is of suitable high quality for its designated application

Our welding inspectors have actually the needed qualifications with years of experience with evaluation and are familiar with a lot of used welding standards and specifications. AQSS has CWI certified examiners.

A Biased View of Aws Cwi

Typically, our inspectors are checking for splits, pits, surface pores, undercut, underfill, missed joints, and various other facets of the weld.

Samples can likewise be taken at intervals throughout the production procedure or at the end of the run. Harmful screening samples are precisely reduced, machined, ground, and brightened to a mirror-like finish. An acid etch is then put on visually draw out the weld, and the sample is then evaluated under a microscope.

Report this page